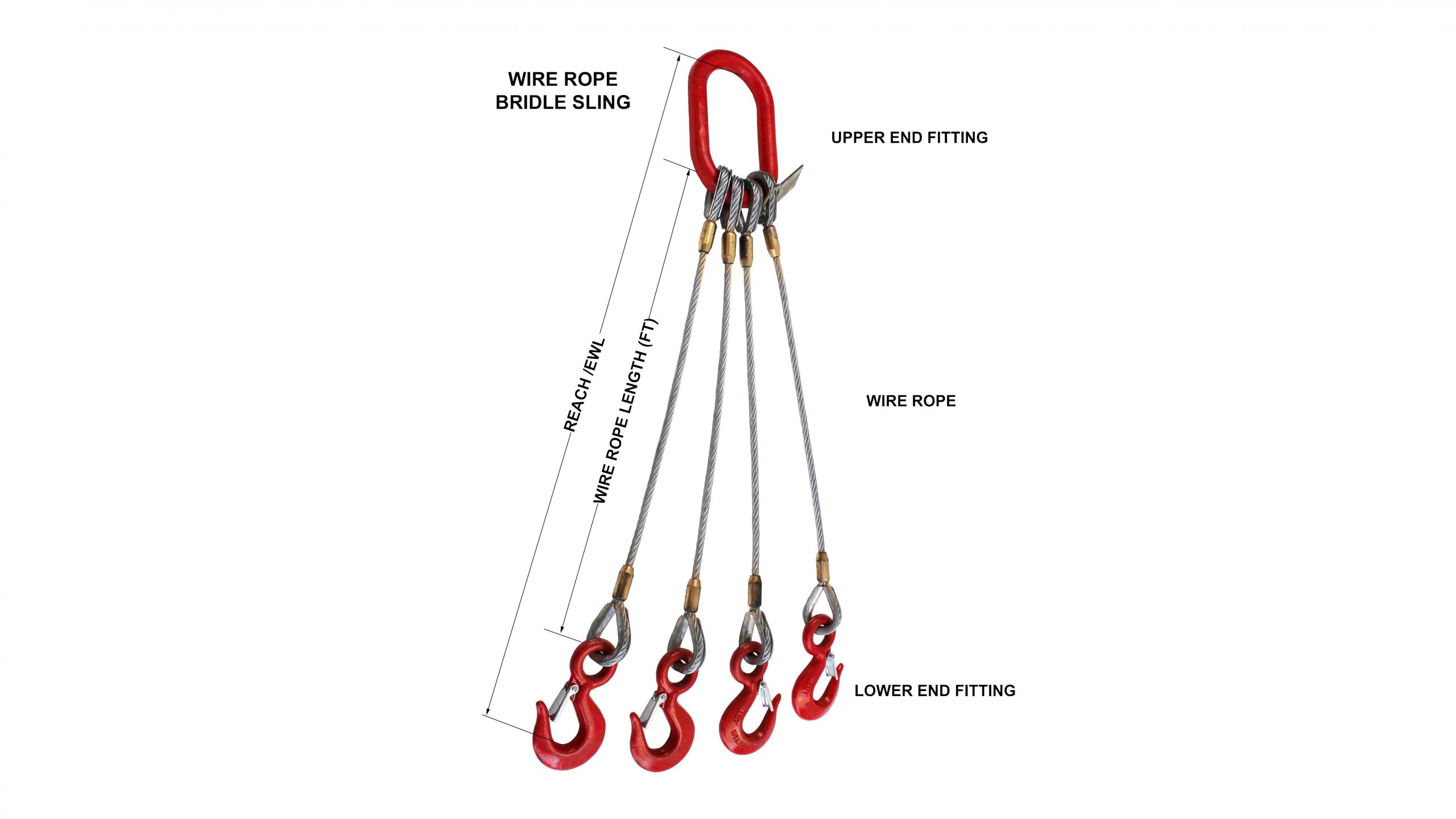

WIRE ROPE SLINGS – HARDWARE

When selecting rigging hardware to be connected to wire rope slings, we encourage that the hardware have a diameter greater than the rope diameter so as to achieve D/d ratio in the eye of the sling greater than 1 to 1. We need to make sure that the WLL of the rigging hardware is greater than the sling tension.

WIRE ROPE SLING CAPACITIES – TONS (2000 LBS.) FLEMISH EYE – ASME B30.9 BASED ON 6 X 19, 6 X 36 STEEL IWRC WITH DESIGN FACTOR 5:1

|

SINGLE LEG WIRE ROPE SLINGS (1-LEG) HORIZONTAL RATED CAPACITY – 6 -strand wire rope with a steel core (IWRC) |

||||

|

WIRE ROPE DIAMETER INC. |

VERTICAL TONS |

CHOKER TONS |

SHACKLE SIZE INCH |

HOOK SIZE MM |

| 1/4″ | 0.65 | 0.48 | 5/16″ | 8 |

| 5/16″ | 1.00 | 0.74 | 3/8″ | 8 |

| 3/8″ | 1.40 | 1.10 | 7/16″ | 8 |

| 7/16“ | 1.90 | 1.40 | 1/2″ | 8 |

| 1/2″ | 2.50 | 1.90 | 5/8″ | 10 |

| 9/16″ | 3.20 | 2.40 | 5/8″ | 13 |

| 5/8″ | 3.90 | 2.90 | 3/4″ | 13 |

| 3/4″ | 5.60 | 4.10 | 7/8″ | 16 |

| 7/8″ | 7.60 | 5.60 | 1″ | 16 |

| 1″ | 9.80 | 7.20 | 1-1/4″ | 19 |

|

2-LEG & 4-LEG WIRE ROPE SLINGS HORIZONTAL RATED CAPACITY – 6 strand wire rope with a steel core (IWRC) |

||||||

| 2-LEG | 4-LEG | |||||

|

WIRE ROPE DIAMETER (INCH) |

60° | 45° | 30° | 60° | 45° | 30° |

| 1/4″ | 1.10 | 0.91 | 0.65 | 2.20 | 1.80 | 1.30 |

| 5/16″ | 1.70 | 1.40 | 1.00 | 3.50 | 2.80 | 2.00 |

| 3/8″ | 2.50 | 2.00 | 1.40 | 5.00 | 4.10 | 2.90 |

| 7/16″ | 3.40 | 2.70 | 1.90 | 6.70 | 5.50 | 3.90 |

| 1/2″ | 4.40 | 3.60 | 2.50 | 8.80 | 7.10 | 5.10 |

| 9/16″ | 5.50 | 4.50 | 3.20 | 11.0 | 9.00 | 6.40 |

| 5/8″ | 6.80 | 5.50 | 3.90 | 14.0 | 11.0 | 7.80 |

| 3/4″ | 9.70 | 7.90 | 5.60 | 19.0 | 16.0 | 11.0 |

| 7/8″ | 13.0 | 11.0 | 7.60 | 26.0 | 21.0 | 15.0 |

| 1″ | 17.0 | 14.0 | 9.80 | 34.0 | 28.0 | 20.0 |

-

- All rated Capacities are based on a D/d ratio of >25:1

-

- Rated Capacities are based on a D/d ratio of >25:1 and choking angle greater thant 135°.

-

- All sling angles refer to the HORIZONTAL angle.

-

- All Rated Capacities (WLL’s) on multiple leg slings are based on EQUAL loading of all sling legs.