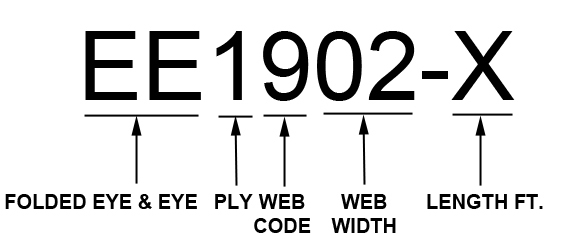

WEB SLINGS TYPE 3: FOLDED EYE – EYE

Web Slings TYPE 3 – FOLDED EYE-EYE

-

- Web Sling made with a FOLDED loop eye on each end with loop eye opening on same plane as sling body.

-

- FOLDED EYE slings are very popular and can be used in all three types of hitches

-

- Our standard FOLDED EYE-EYE web slings come with reinforced lifting eyes.

.jpg)

Polyester Webbing Breaking Strength: 9,800lbs/ Inch Safety Factor: 5:1

| 1-PLY | Vertical Lift (lbs) | Choked Lift (lbs) | Basket Lift (lbs) | Eye Length (inch) | Eye Width (inch) |

| Web Width | |||||

| 1″ | 1,600 | 1,280 | 3,200 | 10″ | 1″ |

| 2″ | 3,100 | 2,480 | 6,200 | 12″ | 1″ |

| 3″ | 4,700 | 3,760 | 9,400 | 12″ | 1.5″ |

| 4″ | 6,200 | 4,960 | 12,400 | 14″ | 2″ |

| 2-PLY | Vertical Lift(lbs) | Choked Lift(lbs) | Basket Lift(lbs) | Eye Length (inch) | Eye Width (inch) |

| Web Width | |||||

| 1″ | 3,100 | 2,480 | 6,200 | 10″ | 1″ |

| 2″ | 6,200 | 4,960 | 12,400 | 12″ | 1″ |

| 3″ | 8,800 | 7,040 | 17,600 | 12″ | 1.5″ |

| 4″ | 11,000 | 8,800 | 22,000 | 14″ | 2″ |

WARNING!! DO NOT EXCEED RATED CAPACITIES

Polyester Webbing Breaking Strength: 9,800lbs/ Inch

Safety Factor: 5:1

-

- Easy use combined with industrial rigging for its lightness and flexibility.

-

- Able to print company names and others.

-

- RED YARN woven into the core of the webbing to serve only as one of many aids in determining whether and when a sling should be removed from service.

POLYESTER SLING CHARACTERISTICS

-

- Low elongation

REMOVAL FROM SERVICE

A web sling shall be removed from service if any of the following are visible:

-

- If sling rated capacity or sling material identification is missing or not readable.

-

- Acid or alkalis burns.

-

- Melting, charring or weld spatters on any part of the web sling.

-

- Holes, tears, cuts, snags or embedded particles.

-

- Broken or worn, stitching in load bearing splices.

-

- Excessive abrasive wear.

-

- Knots in any part of the web sling.

-

- Excessive pitting, corrosion, cracked, distorted or broken fittings.

-

- Any other visible damage that causes doubt as to the strength of the sling.

INSPECTION RECORDS

Written inspection records, utilizing the identification for each sling as established by the user, should be kept on file for all web slings. These records should show a description of the sling and its condition on each periodic inspection.

WEB SLING SAFETY USE CHEMICAL CHART

| CHEMICAL | NYLON | POLYESTER |

| Acid | NO | * |

| Alcohol | OK | OK |

| Aldehydes | OK | NO |

| Strong Alkalis | OK | ** |

| Bleaching Agents | NO | OK |

| Dry Cleaning Solvents | OK | OK |

| Ethers | OK | NO |

| Halogenated Hydrocarbons | OK | OK |

| Hydrocarbons | OK | OK |

| Ketones | OK | OK |

| Oil, Crude | OK | OK |

| Oil Lubricating | OK | OK |

| Soaps, Detergents | OK | OK |

| Water, Seawater | OK | OK |

| Weak Alkalis | OK | OK |

* Disintegrated by concentrated sulfuric acid.

** Degraded by strong alkalies at elevated temperatures.